Projects that employees of the Institute of Turbomachinery, of Lodz University of Technology, work on:

|

Project’s acronym |

AnBaCo |

|

Title or field of the project |

Layers of antibacterial sol-gel with carbon nanoparticles

|

|

No. |

M-ERA.NET2/2019/3/2020

|

|

Goal/Description of the project |

The goal of the AnBaCo project is to create non-toxic, antibacterial, sol-gel coating for various use (handles in public transport, shopping carts, door handles in public toilets, hospitals etc.). It is an upgrade over already implemented technology of sol-gel layers, that replaces toxic nanoparticle of metals (Ag, Cu, Zn) with chemically modified, non-toxic carbon nanoparticles (CNP). These CNP will be chemically modified in order to increase their germicidal properties. Functionality of the coating will be tested in microbiological experiments with selected bacteria strains. In addition, the safety and non-toxicity of the product will be tested and confirmed. The technology will be adjusted for automated production with the use of a Portable Laboratory System (PLS), designed and crafted as a part of this project.

|

|

Partners |

Lodz University of Technology, Technical University of Liberec (the Czech Republic) and PPHU TERMEX Sp. z o.o. (Koszalin, Poland). |

|

Main contractors |

A team lead by dr inż. Anna Karczemska includes scientists from the Faculty of Mechanical Engineering and the Faculty of Chemistry of LUoT: dr inż. Dariusz Witkowski, dr inż. Radosław Wach (Institute of Applied Radiation Chemistry) and a group of researchers from the Institute of Organic Chemistry, under the supervision of prof. Beaty Kolesińska.

|

|

Project’s acronym |

RELIGA-PED |

|

Title or field of the project |

1. Designing a type series of disc-shaped heart valves for ventricles in pediatric ventricular assist device. 2. Extracorporeal pulsatory ventricular assist device for children: RELIGIA HEART PED |

|

No. |

1. 13-0118/10/2011 |

|

Goal/Description of the project |

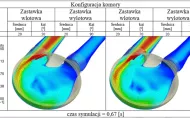

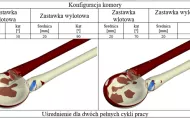

The goal of both project is to design and test the ventricular assist device for children: RELIGIA HEART PED, that consists of pulsatory prosthetic hearts of various shapes and hybrid pulsatory controller for adult VADs, adapted for the features of the pediatric VADs. The work on disc-shaped heart valves had shown that the pumps used are in need of an improvement, which has led to the establishment of Religia Heart PED system improvement project. As a part of research, a series of parametric models and numerical simulations of the flow in pediatric pulsatory VADs (20ml, 30ml, 45ml) has been performed. These VADs had disc-shaped heart valves of the Moll type. Projects have been implemented from 2011 to 2016, in close cooperation with Professor Zbigniew Religa Foundation of Cardiac Surgery Development in Zabrze. Our job was to evaluate the flow in the ventricles and the functionality of valves. We also have made parametric models of the pumps used in the device and an evaluation model of the blood coagulation: ASZ and during the rinse in the chamber. Research incorporated the time-varying variables caused by the movement of membrane and the discs of valves. |

|

Partners |

The Institute of Turbomachinery and the Institute of Material Science and Engineering of the Lodz University of Technology, Professor Zbigniew Religa Foundation of Cardiac Surgery Development in Zabrze, The Institute of Foundry in Kraków, Faculty of Materials Science and Engineering of Warsaw University of Technology. |

|

Main contractors |

The research team, led by prof. dr hab. inż. Krzysztof Jóźwik, included researchers from all the institutions listed above, notably: dr hab. inż. Damian Obidowski, dr inż. Piotr Reorowicz, prof. dr hab. inż. Piotr Niedzielski, dr hab. inż. Witold Kaczorowski, mgr inż. Roman Kustosz, dr hab. inż. Maciej Gawlikowski, prof. dr hab. inż. Jerzy Sobczak, prof. dr hab. inż. Taduesz Wierzchoń, among others (listed in the order corresponding to the institutions, same as above).

|

|

Project’s acronym |

Petrina- Prediction of Endovascular Treatment Results by Individualized Numerical Analysis |

|

Title or field of the project |

Prediction of endovascular treatment results by individualized numerical analysis. |

|

No. |

0056/L-10/2018

|

|

Goal/Description of the project |

The project has been conducted from 2020 to 2023 in the Lodz Institute of Turbomachinery, thanks to the funds from The National Centre for Research and Development. This interdisciplinary project combines the requirements of modern medicine with the methods emblematic of technical universities. Completing this project would enable researchers to design innovative methods of assessing the flow in arteries without the need for many repetitive, difficult numerical simulations. The assessing process will include the available personal data of the patient, previous Fluid Structure Interaction simulations and trained neural networks. With the instruments designed in the project, a vascular surgeon will be able to predict the outcome of their actions with more precision than ever before. |

|

Partners |

Lodz University of Technology |

|

Main contractors |

A team lead by dr inż. Piotr Reorowicz includes researchers from: the Faculty of Mechanical Engineering, the Faculty of Technical Physics, Information Technology and Applied Mathematics (LUoT) and Neurosurgery and Oncology of the Central Nervous System Clinic from Norbert Barlicki Memorial Teaching Hospital No. 1 of Lodz.

Leader:

Members of the team:

|

|

Project’s acronym |

FLEXindustries |

|

Title or field of the project |

Digitally-enabled FLEXibleIndustries for reliable energy grids under high penetration of Variable Renewable Energy Sources (VRES) |

|

No. |

CL4-2021-TWIN-TRANSITION-01-21 |

|

Goal/Description of the project |

As a part of Horizon Europe FLEXindustries, over 17 million euro will be dedicated to the research of innovative solutions for supporting the intelligent energetic transformation in large industry plants. FLEXindustries consortium will create 7 model transformations, that will involve their technical, digital and business aspects. Under the project, a model transformation will be conducted in factories in Turkey, Greece, Bulgaria, Germany, Italy and Polish company K-FLEX Łódź – Uniejów. The partners of this project will install intelligent energy saving systems, renewable energy sources, systems for restoration of heat from waste incineration and solutions for lowering the CO2 emissions. The members of the consortium hope, that the positive behaviors taught as a part of the project will inspire similar transformations in remaining European factories.

The budget for LUoT is 537 750 Euro. For the project, we will construct a prototype ORC (Organic Rankine Cycle) installation, that will enable energy generation from the heat created in the K-FLEX factories in Uniejów. ORC is a popular technology; however, our proposal will incorporate an unconventional turbine design.

Project’s website: https://flexindustries.eu/ |

|

Partners |

36 institutions from across Europe: Italy, Greece, Spain, Germany, Bulgaria, Turkey and Switzerland. |

|

Main contractors |

Grzegorz Liśkiewicz, Władysław Kryłłowicz, Radomir Magiera, Artur Gutkowski, Marcin Łęcki, Krzysztof Kantyka |

Folder: https://flexindustries.eu/wp-content/uploads/2022/11/FLX_leaflet_digital-def.pdf |

|

Project’s acronym |

SAFEcomp |

|

Title or field of the project |

Monitoring of radial compressor during work and protection from instabilities |

|

No. |

LIDER/447/L-6/14/NCBR/2015 Diamond Grant Filip Grapow MINIATUTA 494692, |

|

Goal/Description of the project |

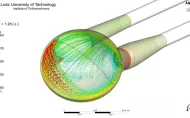

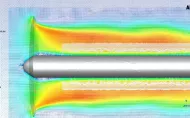

As a part of the LIDER project, the methods of signal analysis, which clearly showcase the signs of local flow instabilities in radial compressor, have been created. Such instabilities occur in compressors that work in conditions of insufficient mass of the stream. The most complex unstable structure is “the pumping phenomenon” which cause global loss of work stability of the active machine and the system it is connected to. We have created a safeguard anti-pumping system which works with industrial compressors. Before the pumping phenomenon some local instabilities can be observed, such as: recirculation in the outlet and/or in the inlet and detachment of the vortex. As a part of the “Diamond Grand” program, a special research station for optical detection of the detachment of the vortex event have been created. With the station, we could observe that phenomena for the first time is such a grand scale and explain the effect of the fusion of vortex detachment cells in vaneless diffuser. The following task was to advance the algorithms which use non-linear methods of signal analysis, that are used to identify unstable flow structures with very high precision. The methods used are: - Our original RDF (Rate of Derrivative Fluctuation) method, based on phase diagrams - EMD (Empirical Mode Decomposition) method - PCA (Principal Component Analysis) method - analysis which incorporates cyclo-stationarity method - Other non-linear methods of signal analysis (e.g. Complex Wavelet Transform)

The high sensibility of the method listed above, has enabled their utilization in MINIATURA project for a new field of research: non-direct measure of the involvement of secondary flows and local flow instabilities in nominal work. The study includes the energy of emerging structures, which is transferred in corresponding frequencies. Additionally, the study showcased a possibility for identifying small changes in the channel’s geometry. This possibility allows early detection of minor damages, and in further perspective, Predictive Maintenance implementation.

|

|

Partners |

University of Edinburgh |

|

Main contractors |

Grzegorz Liśkiewicz, Kirill Kabalyk, Andrzej Jaeschke, Filip Grapow, Michał Kulak, Mateusz Stajuda, David Garcia Cava (University of Edinburgh) |

|

Project’s acronym |

SolarHybrid |

|

Title or field of the project |

Hybrid systems for solar energy conversion |

|

No. |

POIR.04.01.04-00-0019/19 |

|

Goal/Description of the project |

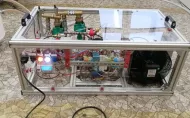

The fourth stage of this project consists of two tasks. The first one is to design and create an external part of a flow loop of the cooling medium, that would have the most optimal parameters for ensuring the circulation of the medium in a given loop, with the hybrid panel demonstrators being the main subject of research. The part is supposed to provide variable parameters of the media flow (pressure and velocity of the flow) in the outlet of a PV/T panel and come equipped with a radiator unit that has regulated efficiency. The second task is to design and create a heat pump which accommodates (cools down) the PV/T panel: The panel increases its efficiency when it is cooled down. Additionally, the heat generated by the heat pump will be used to warm up the tap water for domestic use. |

|

Partners |

Project coordinator: prof. dr hab. inż. Zbigniew Lisik, The Department of Semiconductor and Optoelectronic Devices, The Institute of Material Science and Engineering of LUoT and FLEXIPOWER GROUP SP. Z O.O. SP.K. |

|

Main contractors |

The employees assigned to the fourth stage of the project are dr hab. inż. Artur Gutkowski, dr inż. Marcin Łęcki and dr inż. Zbigniew Cebulski. |

|

Project’s acronym |

Lider |

|

Title or field of the project |

Intensification of heat exchange processes in the immediate surroundings of the heat pipes and their usage in an innovative heat exchanger – research incorporating PIV (Particle Image Velocimetry) method.

|

|

No. |

LIDER/08/42/L-3/11/NCBR/2012

|

|

Goal/Description of the project |

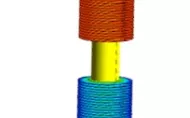

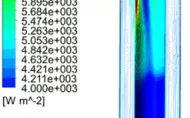

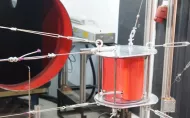

During the work done for this project, an analysis of heat exchange processes in heat pipes (type of heat exchanges) was conducted. We examined the heat pipes of varying geometry using different working mediums and flow disrupting elements, such as ribs, spiral and disks placed around the examined heat pipe. Numerical analyses had been performed, which enabled the calculation of efficiency and flow round of the heat pipe. The most effective variant of the pipe has been used to build the heat exchanger, for recovery of warmth from the battery of heat pipes. The prototype has been created and tested in various working conditions.

|

|

Main contractors |

The team lead by dr inż. Grzegorz Górecki, joined by researchers from the Faculty of Mechanical Engineering of LUoT: dr inż. Marcin Łęcki, mgr. inż. Aneta Banasiak and others. |

|

Title or field of the project |

Local validation of two-equation turbulence models on the basis of heat exchange in the air in lamellar heat exchangers. |

|

No. |

MINIATURA 5 2021/05/X/ST8/01896 |

|

Goal/Description of the project |

The project, a part of Miniatura 5 contest, aimed to determine the best turbulence model which would describe the heat exchange in the flow through a channel of a lamellar heat exchanger. A series of numerical simulations will be performed with a variety of turbulence models, to compare local coefficients of heat with empirical data from literature for the geometry of one- and two-row heat exchangers. The analysis of different solutions will allow us to select the best model of turbulence, and a one that would be adaptable to the changes in the constants, so that it could imitate the experimental fields of local heat-gathering factors with the highest precision. Reconstructing the flow structures through numerical methods will be verified by a visualization method: the “smoke wire” technique. This technique enables the detection of electricity line in the flow. It is easier and much cheaper than Particle Image Velocimetry or Laser Doppler Velocimetry. A prototype station with a small section of a heat exchanger, embedded into a channel with a forced air flow will be created. |

|

Main contractors |

dr inż. Marcin Łęcki |

|

Project’s acronym |

TurbORC70 |

|

Title or field of the project |

Building and constructing ORC turbines for research purposes

|

|

Goal/Description of the project |

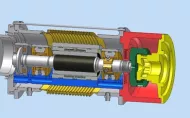

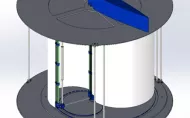

Conceptualization, design and creation of a high-speed prototype of a turbogenerator with an innovative supersonic radial turbine (70kW of power) and hybrid load bearing lubricated with a liquid fraction of the working medium of ORC circulation and an active longitudinal magnetic bearing. |

|

Partners |

Institute Of Fluid-Flow Machinery, Polish Academy of Sciences in Gdańsk |

|

Main contractors |

Flow Machines Diagnostics and Automation Facility of The Institute of Turbomachinery of LUoT. prof. dr hab. inż. Zbigniew Kozanecki dr hab. inż. Jakub Łagodziński dr inż. Eliza Tkacz dr inż. Małgorzata Gizelska mgr inż. Sylwester Więckowski Bohdan Pawłowski |

|

Project’s acronym |

TurbORC3 |

|

Title or field of the project |

Building and constructing prototypical prosumer ORC turbines for agroenergetic complexes.

|

|

Goal/Description of the project |

Conceptualization, project and construction of the prototypes I, II and IV of high-speed turbogenerators with a fourfold radial turbine and bearings lubricated with the steam from a working medium, for the experimentation and research on the circuit. Conceptualization, project and construction of the prototype III of high-speed turbogenerator with a supersonic radial turbine and gaseous load bearings lubricated with the steam from a working medium, for the ORC circuit requirements. |

|

Partners |

Institute Of Fluid-Flow Machinery, Polish Academy of Sciences in Gdańsk |

|

Main contractors |

Flow Machines Diagnostics and Automation Facility of The Institute of Turbomachinery of LUoT. prof. dr hab. inż. Zbigniew Kozanecki |

|

Project’s acronym |

AFB – Air Foil Bearings |

|

Title or field of the project |

Air bearings for high-speed, oil-free compressors |

|

Goal/Description of the project |

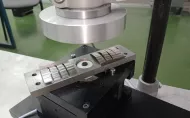

The aim of this project is creating air-lubricated foil bearings, for the oil-free compressors produced by Pankl Turbosystems GmbH (in Mannheim, Germany). The typeseries of the target machines contains several items of various size, efficiency and nominal rotation speed. The technology of foil bearings, developed in our Institute of Turbomachinery over several years, has been successfully adapted and utilized by Pankl Turbosystems GmbH in their machines. As a part of the project, current inventions are improved, and new variants of the foil bearings are being created. All modernizations of existing bearing designs aim for increasing their load capacity, durability and reliability. Pankl Turbosystems GmbH compressors that use bearings designed by our Institute, alongside the rotors produced by them, are used in the systems that require the provision of clean, non-oiled air.

|

|

Partners |

Lodz University of Technology, Pankl Turbosystems GmbH, Mannheim |

|

Main contractors |

The team, led by dr hab. inż. Jakub Łagodziński, consists of researchers from Flow Machines Diagnostics and Automation Facility of IoT LUoT. |

|

Project’s acronym |

FlexiSav |

|

Title or field of the project |

Savonius Windmill with varying geometry of blades / Wind Energy |

|

Goal/Description of the project |

Savonius windmills have various advantages, such as simple construction or being unaffected by the changing direction of the wind. However, their main flaw is low efficiency. The aim of this project is to create and advance a new design of a wind turbine, with varying blade geometry. The blades, made from an elastic material, bend during the spin of the rotor, to increase the positive torque of the pressing blade, and reduce the negative torque of the returning blade. As a part of the project, the work to improve this turbine concept is in progress, using both experimental and numerical methods. Advanced numerical simulations of the flow, with several variants of its geometry and type are created by the Institute. The simulations use deformable mesh and compression in accordance with structural simulations. Model research on turbine in aerodynamic tunnel that the Institute has on site is also being conducted. The invention is protected by EP3702610B1 patent. |

|

Main contractors |

The team that has created the invention and is working on its improvement consists of: prof. dr hab. inż. Krzysztof Jóźwik, dr hab. inż. Krzysztof Sobczak, dr hab. inż. Damian Obidowski, dr inż. Piotr Reorowicz and mgr inż. Emil Marchewka – who researched the turbine as a part of his PhD thesis. |

|

More information |

1. Marchewka, E., Sobczak, K., Reorowicz, P., Obidowski, D., & Jóźwik, K. (2022). Influence of Tip Speed Ratio on the efficiency of Savonius wind turbine with deformable blades. Journal of Physics: Conference Series, 2367(1), p. 012003. |

|

Project’s acronym |

NUTRIA |

|

Title or field of the project |

Circular bearing rotor in a system, Tandem for Polish electromobility. |

|

No. |

LIDER/57/0233/L-11/19/NCBR/2020 |

|

Goal/Description of the project |

The aim of this project is to create and research the concept of a bearing rotor for a small electric flying vehicle dedicated for transport of people and objects. The final outcome of the project will be a new rotor concept, for a VTOL (Vertical Take-Off and Landing) flying vehicle. Due to the need of the vehicle to be a compact block, in such constructions engineers most often choose multi-rotor solutions, for example with backward rotors. It enables a heavy thrust with relatively small rotor surface, but with the compensation in high increase of generated noise. To reduce it, as well as to increase the safety of the whole construction, we plan to create a casting around the rotor. This solution, however, requires a lot of precision and care: correct design can increase the performance of rotors group, incorrect will generate high resistance in continuous movement of the vehicle. The further improvement of the rotor’s performance can be find, according to our team in biomimicry, such as profiling the edge of the rotor’s fillet to imitate the wings of owls. The design phase will include experiments in aerodynamic tunnel (measurements of power and thrust of the engine, research on the streamline) and in an anechoic chamber (measuring acoustic emissions of the rotor in various locations and distance); as well as numerical research that will include the creation of numerical models of the flow and their implementation in the rotor’s optimalization. |

|

Partners |

Lodz University of Technology |

|

Main contractors |

The project is carried out by a team of aerodynamic experts from our Institute of Turbomachinery: dr inż. Andrzej Jaeschke, dr inż. Michał Kulak, dr inż. Krzysztof Olasek, mgr inż. Emil Marchewka and mgr inż. Mateusz Stajuda under the leadership of dr. inż. Michał Lipian. The htw saar (Hochschule für Technik und Wirtschaft des Saarlandes, Germany) and the Technical University of Sofia (Bulgaria) have expressed their interest in joining the research on this project. |

|

Project’s acronym |

NINLIL |

|

Title or field of the project |

Household wind turbine for the European prosumer micro renewable energy source |

|

No. |

POLTUR5/133/NINLIL/2022 |

|

Goal/Description of the project |

The main goal of this project is to design an innovative, highly efficient vertical-axis wind turbine with a vertical axis, suitable for urban and suburban areas, and capable of integration with other Renewable Energy Sources (RES). The project is based on the ENLIL wind turbine developed by the Turkish company Devecitech. Polish partners will enhance the project with their contributions: Lodz University of Technology will design the generator and automation/control unit and conduct in-situ tests of the prototype in urban environments representative of Eastern European cities. Enerwis Sp. z o.o. will ensure the prototype meets RES industry standards and facilitate collaboration with third-party partners from academia and business. The project will focus on experimental research. Partners will design, create, and evaluate components of the turbine, including its generator and control system. Lodz University of Technology will conduct research at three facilities: the Institute of Turbomachinery (I12), where the turbine's performance in the target environment will be tested; Institute of Mechatronics and Information Systems (I25), which will design and build a dedicated generator for the turbine; and Institute of Electrical Power Engineering (I22), responsible for the automation and control systems. The ultimate goal is to advance the project to the full TRL7 stage and begin the certification process to launch the machine for sale.

|

|

Partners |

Lodz University of Technology (Consortium leader), Enerwis Sp. z o.o., Devecitech (Turkey) |

|

Main contractors |

Project management is done by Michal Lipian, PhD, who’s also responsible for the research done at the Faculty of Mechanical Engineering. Anna Firych-Nowacka, PhD, coordinates the works at the Faculty of Electrical, Electronic, Computer and Control Engineering Devecitech is the author of the original wind turbine concept, the development team is headed by Kerem Deveci. The commercial aspects of the project are coordinated by team of Enerwis Sp. z o.o., headed by Marek Jankowski. |

|

Project’s acronym |

MAPIATO |

|

Title or field of the project |

Mathematical predictions of the effects of the treatment of intracranial aneurysms |

|

No. |

LIDER14/0034/2023 |

|

Goal/Description of the project |

Illnesses of cardiovascular system are still the most frequent illnesses (they are more common than cancer) and remain the leading cause of death. One of the most lethal types of them, are intracranial aneurysms, that can burst without a special treatment, leading to various disabilities, coma or death. Due to this, selecting the best possible treatment and a technique of preventing the aneurysm from bursting is most crucial for the patient’s health. Unfortunately, all currently available methods of this have some complications and sometimes cannot be applied in a given patient’s situation or will not cause any improvement. Currently, in the field of medical devices, there is no software that would objectively present an impact over hemodynamics of patient’s blood flow that a given treatment would have caused, as well as how the tension of aneurysm walls would have changed or whether the treatment would have led to increased chances of thrombosis and aneurysm’s treatment against its rupturing. The goal of this project is to create an interactive MAPIATO software, that will support the doctors in choosing the best brain aneurysm treatment, personalized for a given patient’s case. The program will do this by analyzing data from an array of numerical simulations. Using the morphometric parameters of a given patient’s aneurysm, and selecting the possible treatment strategy, the doctor would receive a report on the changes of blood hemodynamics around the aneurysm. Objective, numerical data allow the doctors to predict the outcomes the chosen strategy would cause, so then the doctors could eliminate the ineffective strategies, and choose the best one for the situation of a patient. Data generated by MAPIATO is based on neural network and computational fluid dynamics (CFD) calculation method – meaning it also utilizes complex in-silico analyses. |

|

Partners |

Lodz University of Technology |

|

Main contractors |

Leader: dr inż. Zbigniew TYFA Team members: dr n. med. Karol Wiśniewski dr inż. Justyna Gaj dr inż. Olga Jarzyna mgr inż. Bartosz Kawecki dr inż. Krzysztof Olasek mgr inż. Paweł Tarasiuk |

|

Project’s acronym |

HE-ART |

|

Title or field of the project |

Setting a course for hybrid electric thermal turboprops in regional aviation |

|

No. |

101102013 — HE-ART — HORIZON-JU-Clean-Aviation-2022-01 |

|

Goal/Description of the project |

In the next 20 years, regional market growth and a greater demand for lower emissions will push regional aviation towards innovative solutions to decarbonise the sector. The EU-funded HE-ART project will demonstrate the viability of a hybrid electric turboprop within a dedicated integrated “full-scale” ground test demonstrator. By combining an electric drive train with an ultra-efficient thermal turboprop engine and 100 % sustainable aviation fuel compatibility, HE-ART will target efficiency improvement and reduction of GHG emissions up to 30 %. Moreover, it will integrate new technologies including core thermal engine, electric drive train, electrical distribution, gearbox, propeller, nacelle and heat exchanger. Leading engine, propeller and aircraft manufacturers, research organisations and universities will collaborate to ensure the project’s success. In this projects, our Institute performs numerical simulations of propeller's blade and optimalizations of that blade focusing on lowering the generated noise in various working environments. Our goal is to design new shapes of propeller and blade, which would lower the intensity and volume of the noise generated while keeping the same aerodynamic proficiency. To reach this goal, we are cooperating with Airbus Helicopters and researchers from the Catholic University of Leuven. |

|

Partners |

VON KARMAN INSTITUTE FOR FLUID DYNAMICS, UNIVERSITE CATHOLIQUE DE LOUVAIN (Catholic University of Leuven), THIOT INGENIERIE, SKYLIFE ENGINEERING SL, SINTEF ENERGI AS, SINTEF AS, SEVILLA CONTROL S.A., SAFRAN TRANSMISSION SYSTEMS POLAND SP Z O.O. , SAFRAN TRANSMISSION SYSTEMS, SAFRAN NACELLES, SAFRAN HELICOPTER ENGINES, SAFRAN ELECTRICAL & POWER, ROLLS-ROYCE ELECTRICAL NORWAY AS, RATIER FIGEAC SAS, POLITECHNIKA LODZKA, OFFICE NATIONAL D'ETUDES ET DE RECHERCHES AEROSPATIALES, NORGES TEKNISK-NATURVITENSKAPELIGE UNIVERSITET NTNU, LEONARDO - SOCIETA PER AZIONI, INGPULS GMBH, FUNDACION ANDALUZA PARA EL DESARROLLO AEROESPACIAL, ECOLE CENTRALE DE LYON, COMPANIA ESPANOLA DE SISTEMAS AERONAUTICOS SA, CENTRE NATIONAL DE LA RECHERCHE SCIENTIFIQUE CNRS, CENTRE EUROPEEN DE RECHERCHE ET DEFORMATION AVANCEE EN CALCUL SCIENTIFIQUE, CENTRE DE RECHERCHE EN AERONAUTIQUE ASBL - CENAERO, CENAERO FRANCE, CAPGEMINI ESPANA SL, CALYOS, AVIONS DE TRANSPORT REGIONAL, AIRBUS OPERATIONS SAS, AIRBUS HELICOPTERS POLSKA SP. Z O.O., AIRBUS HELICOPTERS DEUTSCHLAND GMBH, AIRBUS HELICOPTERS, AIRBUS DEFENCE AND SPACE SA, "INSTITUTUL NATIONAL DE CERCETARE-DEZVOLTARE AEROSPATIALA ""ELIE CARAFOLI""- INCAS BUCURESTI", ROLLS-ROYCE PLC |

|

Main contractors |

Project coordinator: prof. dr hab. inż. Krzysztof Jóźwik contractors: dr hab. inż. Damian Obidowski prof. uczelni dr hab. inż. Krzysztof Sobczak prof. uczelni dr hab. inż. Adam Papierski prof. uczelni dr inż. Michał Kulak dr inż. Michał Lipian dr inż. Piotr Reorowicz dr inż. Zbigniew Tyfa mgr inż. Maciej Podsędkowski mgr inż. Rafał Konopiński |

|

Project’s acronym |

FRONTSH1P |

|

Title or field of the project |

FRONTSHIP: A FRONTrunner approach to Systemic circular, Holistic & Inclusive solutions for a New Paradigm of territorial circular economy |

|

No. |

H2020-LC-GD-2020-3 |

|

Goal/Description of the project |

The project is based in the Łódzkie region of Poland, which has a dual identity—traditionally reliant on coal extraction while also being a pioneer in circular (bio)economy since the early 2000s. Renowned for its innovation, the region has emerged as a leader in the circular economy field. Over the next four years, FRONTSH1P aims to propel the Łódzkie region through a green and just transition away from its linear economic foundation. This shift involves decarbonization and territorial regeneration, with the project showcasing four Circular Systemic Solutions (CSS) targeting key sectors: Wood Packaging, Food & Feed, Water & Nutrients, and Plastic & Rubber Waste. Each CSS, developed for decarbonization, is designed to be highly replicable, with their effectiveness demonstrated through implementation in four other European regions: Campania (Italy), Sterea Ellada (Greece), Norte (Portugal), and Friesland (the Netherlands). Through the creation of Circular Regional Clusters, FRONTSH1P will actively engage a diverse array of local, regional, and national stakeholders from both the public and private spheres. This ensures inclusivity, preventing anyone from being left behind in the pursuit of sustainable and circular solutions. |

|

Partners |

K-FLEX POLSKA SP ZOO Research and Innovation Centre Pro-Akademia Centre for Promotion and Development Civil Initiatives University of Lodz Lodz Metropolitan Area Association Lodzkie Region Inter-Municipal Union BZURA Parzeczew KPMG Advisory Sirmax Polska Sp. z o.o. Leda Polymer Libera Università di Bolzano Sviluppo Tecnologie e Ricerca per l’Edilizia Sismicamente sicura ed ecoSostenibile Scarl Consorzio per la promozione della plastica Proplast Gruppo di Azione Locale Irpinia Novamont S.p.A. Stam srl. Carmasciando Società Agricola Srl Carmasciando National Technical University of Athens ETHNIKO KENTRO EREVNAS KAI TECHNOLOGIKIS ANAPTYXIS Certh Region of Central Greece Municipality of Levadia Laboratório Nacional de Energia e Geolo Laboratorio Iberico Internacional de Nanotecnologia Comissão de Coordenação e Desenvolvimento Regional do Norte CCDR-Norte Fundación CARTIF Agencia Estatal Consejo Superior de Investigaciones Científicas CSIC Vereniging Circulair Friesland Province of Friesland Waste4ME European Association of Development Agencies Eurada VELTHA ivzw Promix Solutions Burkhardt GmbH |

|

Main contractors |

Dr hab. inż. Grzegorz Liśkiewicz, prof. uczelni Dr hab. inż. Damian Obidowski, prof. uczelni Dr inż. Piotr Reorowicz Dr hab. inż. Krzysztof Sobczak, prof. uczelni |